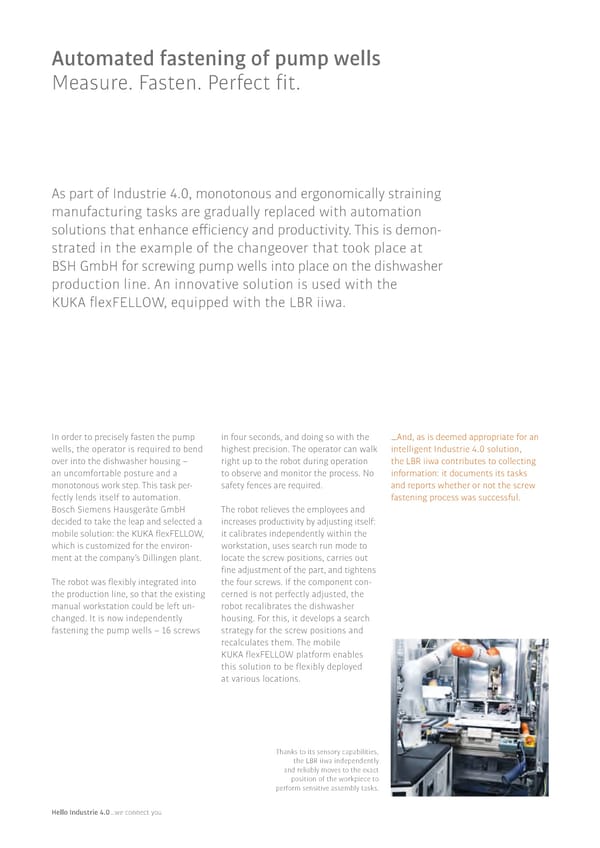

Automated fastening of pump wells Measure. Fasten. Perfect fit. As part of Industrie 4.0, monotonous and ergonomically straining manufacturing tasks are gradually replaced with automation solutions that enhance e昀昀iciency and productivity. This is demon- strated in the example of the changeover that took place at BSH GmbH for screwing pump wells into place on the dishwasher production line. An innovative solution is used with the 阀阀 昀氀exFELLOW, equipped with the LBR iiwa. In order to precisely fasten the pump in four seconds, and doing so with the �And, as is deemed appropriate for an wells, the operator is required to bend highest precision. The operator can walk intelligent Industrie 4.0 solution, over into the dishwasher housing – right up to the robot during operation the LBR iiwa contributes to collecting an uncomfortable posture and a to observe and monitor the process. No information: it documents its tasks monotonous work step. This task per- safety fences are required. and reports whether or not the screw fectly lends itself to automation. fastening process was successful. Bosch Siemens Hausgeräte GmbH The robot relieves the employees and decided to take the leap and selected a increases productivity by adjusting itself: mobile solution: the KUKA flexFELLOW, it calibrates independently within the which is customized for the environ- workstation, uses search run mode to ment at the company’s Dillingen plant. locate the screw positions, carries out fine adjustment of the part, and tightens The robot was flexibly integrated into the four screws. If the component con- the production line, so that the existing cerned is not perfectly adjusted, the manual workstation could be left un- robot recalibrates the dishwasher changed. It is now independently housing. For this, it develops a search fastening the pump wells – 16 screws strategy for the screw positions and recalculates them. The mobile KUKA flexFELLOW platform enables this solution to be flexibly deployed at various locations. Thanks to its sensory capabilities, the LBR iiwa independently and reliably moves to the exact position of the workpiece to perform sensitive assembly tasks. Hello Industrie 4.0�we connect you

Embracing Industrie Page 77 Page 79

Embracing Industrie Page 77 Page 79