Embracing Industrie

This document introduces KUKA's engagement and innovations in Industrie 4.0, emphasizing connectivity and digital transformation in industrial settings.

Hello Industrie 4.0 �we connect you

The digital transformation is now. Let us connect you. The added value of integrated, globally interconnected value chains is acknowledged throughout the world. Companies are opening up to the digital transformation in order to successfully compete in the markets of the future. As a thought leader and trailblazer for Industrie 4.0, 阀阀 supplies intelligent solutions for maximizing the 昀氀exibility of the entire process chain – from consultancy and conceptual design through to the complete implementation of individual requirements. With the expertise to help you step successfully into the future world of production, 阀阀 is transforming the here and now.

Dr. Till Reuter Chief Executive O昀昀icer 阀阀 Aktiengesellschaft Hello Industrie 4.0�we connect you

» It is time for us to help business to fully exploit the potential of Industrie 4.0.« 04�05

A collaborative approach is required in order to leverage the entire potential of Industrie 4.0. One thing is for sure: Industrie 4.0 has arrived in industry worldwide. Transformation towards a globally networked and integrated economy is taking place at all levels. Almost half the German companies from the manufacturing sector are already employing Industrie 4.0 applications. Most of them are focusing on optimizing individual processes from an economic perspective and increasing output. Every second company is investing in digitization to make production more 昀氀exible. Another 20 percent of the companies are planning to implement digitization. The desire is for this to be achieved quickly and in accordance with individual customer requirements. The primary focus here is on the proven success factors of the economy: greater e昀昀iciency, greater productivity and higher speed. Some people still regard this development anxiously. However, the opportunities for digital transformation stem from us challenging traditional thinking. The digital world is not waiting for us. It is developing at a breathtaking pace – and anyone who wants to be on the winning side must clearly take a leading role. The integrated networking of production is an important and correct milestone on this road. But we must also make sure that our supply chains and our business models keep pace with this new era. Moreover, it is important that Industrie 4.0 does not remain the sole preserve of large corporations. Every company should have the opportunity to participate in this technological revolution. No matter Hello Industrie 4.0�we connect you

what sector they come from or how big they are. Industrie 4.0 solutions must therefore be tailored in a wide range of di昀昀erent dimensions and for varying goals and target groups. It is ultimately not about convincing industry of an abstract model of digital networking but rather about technology and tools that enable companies to generate quite speci昀椀c added value in their competitive environment. In this connection, we also consider the abstract search for “the one right Industrie 4.0 platform” to be of little value. 阀阀 has very deliberately opted for a di昀昀erent approach. An approach that focuses on the goal-driven analysis of our customers’ requirements. An integrative concept in which suppliers, partners and specialists for external expertise are actively incorporated in the digital strategy of our customers. 阀阀’s key added value lies in the capability of seamlessly uniting expertise from the digital and real worlds. The digital transformation necessitates a radical change in thinking on the part of all those involved. The world in which everything is interconnected will become not just more interactive and 昀氀exible but also more complex. Any action in the value chain will trigger a reaction at another point. And that will also permanently change the way we work and how we set about 昀椀nding solutions. For this reason, 阀阀 is setting a clear course by infusing the principal thematic areas of Industrie 4.0 with its own expertise. 06�07

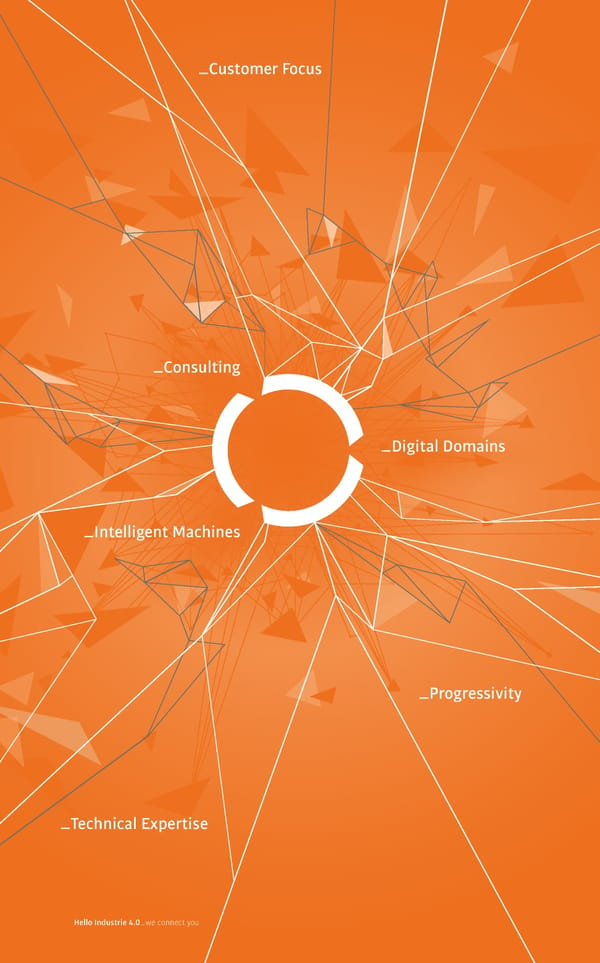

�Customer Focus �Consulting �Digital Domains �Intelligent Machines �Progressivity �Technical Expertise Hello Industrie 4.0�we connect you

Our “Intelligent Machines” and “Digital Domains” make for a seamless connection between the real and digital worlds. And this can be scaled to any conceivable degree in the value chain between the shop 昀氀oor and the cloud. One speci昀椀c example might be the intelligent networking and 昀氀exibilization of individual production processes. It may also be a matter of connecting complex production systems and integrating them into an existing IT infrastructure or of implementing entirely new business models with comprehensive interfacing to the cloud, Big Data or predictive analytics tools. We know from countless projects that the full potential of Industrie 4.0 does not unfold until solution concepts holistically encompass the issues facing companies with a high level of competence in all customer-speci昀椀c topic clusters. We have pooled specialists from a broad range of 昀椀elds in a dynamic, interdisciplinary Industrie 4.0 accelerator unit. Our aim is to reveal to our customers at the outset of the planning phase all added value that they stand to gain from digitization. And then to accompany them with our project expertise. In this way, companies also obtain direct access to 阀阀’s global ecosystem. A network of highly quali昀椀ed partners, integrators and suppliers from all areas of the digitized value chain. 08�09

Global. Dynamic. Fast-growing. KUKA addresses the global growth markets with holistic solutions.

�Electronics �Healthcare �Aerospace �Energy �Metal industry �Automotive �E-Commerce / Retail �Consumer goods

Automotive On the data superhighway to the future The automotive industry is undergoing an epochal change. In the age of e-mobility, intelligent vehicles and completely new mobility services, the industry is facing far-reaching changes – from development through to production and logistics. So, the time is ripe for decisive technical and entrepreneurial challenges to be faced. This is the only way that existing competitive advantages can be secured, or new ones established. As a world market leader, we have already been the strategic partner for all important manufacturers for decades. This is because even today, 阀阀 delivers scalable concepts and solutions for the smart factory of tomorrow. In the automotive industry, new market that is capable of coping with the fast- conditions are leading to structural paced change of time. Together with our changes of wide-reaching import. customers, we are already implementing The focus is on the need for vehicles agile, intelligent production solutions that customers all over the world 昀椀nd today, which will turn these dynamic and exciting, at the same time keeping pace reactive worlds of production into reality. with the growing trends and technical development in an extremely 昀氀exible way. Irrespective of whether we are Seamless integration into the existing talking about new powertrain concepts, ecosystem intelligent driver assist systems or totally innovative mobility solutions in the These solutions are providing a key im- �Now is the time to address the decisive individual case – what is crucial when petus for future-oriented production technical and entrepreneurial challenges it comes to sales success is that the concepts. As a driver and pioneer in in order to develop and establish new time between the initial concept and Industrie 4.0 and the Internet of Things, competitive advantages, expand existing market launch must be kept short, and we are developing hardware and soft- ones and maintain these in the long term. sustainably so. This is a requirement ware solutions that achieve maximum that can only be met in the long term variability, availability and greater with intelligently networked value chains. throughput. Intelligent components for Consequently, the market is demanding a fully digitized value chain can be 昀氀exible, robot-supported automation integrated seamlessly into existing ecosystems. Hello Industrie 4.0�we connect you

Maximum availability for greater throughput, plannable ROI Customer-speci昀椀c human-robot collaboration for the smart factory Agile, networked Industrie 4.0 solutions towards a fully digitized value chain 12�13

Greater e昀昀ectiveness and a lower error rate Optimal complement to and relief for skilled workers Development of holistic HRC solutions for customer- speci昀椀c applications Hello Industrie 4.0�we connect you

Metal industry In the crucible of the data revolution Trains pass safely through the transport systems of global cities. Modern agricultural machinery ensures that billions of people can be fed, while highly developed construction machinery forms the foundation of today’s infrastructure. The metal industry makes life as we know it possible. For our customers in these central processing sectors, it is important to manufacture large and complex machines that are processed to perfection down to the smallest detail. This is a challenge that robotic automation solutions were made for. And we supply intelligent, networked concepts for this. Our many years of experience mean we that work with pin-point accuracy are highly familiar with the challenging today. Innovative software technologies tasks faced by the metal industry. such as 阀阀.ArcTech, 阀阀.SeamTech We are familiar with the demanding or ROBOTstar System Software allow fast production conditions and have already con昀椀guration and evaluation of welds worked together with customers from and data. In this way, even during pro- the metal industry to implement numer- duction we ensure that the ultimate ous solutions enabling sustainable, quality check is carried out, and we are e昀昀icient production. With our broad already supplying the technologies to portfolio of industrial robots adapted to link this to the cloud today. the exacting requirements of the metal industry of tomorrow, we supply the Companies in the metal industry operate �Robot-based automation concepts from entire spectrum from robots right up to in a 昀椀ercely competitive environment. 阀阀 enable smooth, safe collaboration cells and complete systems. Many of our International competitors are creating between humans and machines. robot models are produced in special price pressure. An increasing shortage versions, such as for particularly hot or of skilled labor and demographic change wet environments. are leading to personnel bottlenecks. As a result, new robot-based automation In spite of the di昀昀icult production condi- solutions are needed to optimally tions and extreme time pressure, the support skilled workers in the workplace greatest possible freedom from defects and provide supplementary assistance is required. The customer wants to be at decisive points – even in cramped able to rely on the product 100%. 阀阀 or hazardous environments. We stand combines all of this expertise within beside our customers in developing the company in order to already supply tailormade and safe human-robot collab- groundbreaking Industrie 4.0 solutions oration solutions together. 1414�15�15

Energy On the side of the energy visionaries Automation partner for key technologies in e-mobility and renewable energy The latest battery manufacturing processes Climate change is one of the greatest global challenges. Notwithstanding whether the subject is e-mobility or the use of renewable energies – the mass availability of high- performance energy storage systems is the central element in the success of the shift in energy policy. As a key technology for the future, the energy market o昀昀ers gigantic growth and innovation potential, although it is also crucial for complex, technological and economical challenges to be resolved in the entire production process. Against this backdrop, we are acting as partners to manu- facturers and investors as well as other technology providers to jointly implement future-oriented automation concepts which will make the shift in energy policy a successful model in both ecological and commercial terms. Comprehensive documentation of production processes Hello Industrie 4.0�we connect you

Energy storage systems form the critical that are hard to connect, as well as in assembly, ensure comprehensive docu- interface between energy production and the development of intelligent, 昀氀exible mentation of the production processes. energy consumption. At present, the automation concepts that permit eco- This is an important factor in ensuring solutions available for this are still cost nomical mass production – even for safe operation of high-energy storage intensive to produce and subject to signi- a large number of variants and shapes. systems during everyday use. 昀椀cant technological change. Researchers are looking at a blend of in-situ energy storage systems, pumped storage systems A partner for individual and decentralized battery back-ups as automation solutions an appropriate solution for storing energy from solar installations. At the same As part of this, we combine the know- �Intelligent high-tech solutions from time, work is being carried out world- ledge and experience of various technical 阀阀 thus make an important wide on compact battery concepts with disciplines to search for and implement contribution towards making the energy high energy density in the e-mobility holistic solutions – whether for the transition a global success story. sector – which is decisive for the overall materials used, the module design, the concept of the shift in energy policy. connecting technology or 昀椀nal production. In this environment, 阀阀 is involved At the same time, our intelligent and with innovative joining techniques for networked automation processes, for materials such as copper and aluminum example in battery production and 16�17

Electronics Technical innovation setting the pace “Who is interested in yesterday’s technical highlights today?” This sentence sums up the electronics sector. The market is hungry for innovations and the immediate availability of the latest products. The Internet of Things will increase the pressure on companies many times over through a multitude of new product ideas. As a result, changes will form part of everyday survival training. Enormously shortened lifecycles accompanied by tough price wars present manufacturers with a herculean task, however: they will have to produce and deliver massive quantities of premium products within an extremely short time and with maximum reliability. 阀阀 knows where the crunch points of the industry are and is working with customers to develop automation solutions that are extremely 昀氀exible. More intensive media usage, individu- Thought leader and trailblazer As a thought leader and trailblazer for alization and fast product lifecycles lead for Industrie 4.0 Industrie 4.0, we enable our customers to greater performance and lower costs. to respond directly to market changes To enable smart products to be produced In our TechCenters, we are working and to match the requirements of quickly and successfully for this fast- globally on the latest technologies and consumers at any time. This is true, for paced world, 阀阀 is, among other future scenarios. As a result, we are example, with our KR 3 AGILUS – deve- things, developing “ready2�use” packages always capable of developing modular, loped specially for assembly and handling together with its customers speci昀椀cally robot-based automation solutions and of small parts. This lightweight robot for this area. These are innovative concepts together with the customer – has the agility and dynamism to accom- automation solutions that deliver developments that are increasingly plish an extremely wide range of tasks numerous commercial bene昀椀ts to the able to accomplish the speci昀椀c tasks in small, compact and cost-e昀昀ective customer. The precon昀椀gured robot right out of the box. Together with our production cells. The result: top perfor- packages simplify installation and partners and customers, we develop mance, maximum output and extreme commissioning, increase output, and concepts for automation and application precision with very short cycle times. make production more modular. solutions, carry out feasibility studies, work on demos and on-site product tests. �Our 昀氀exible automation solutions such as “ready2�use” enable our partners to meet the ever-changing requirements of the market optimally at all times. Hello Industrie 4.0�we connect you

The product cycle of electronics Consistent quality thanks products in the industry to high precision is less than 6 months Flexible automation solutions and High availability and thus ideal smart manufacturing for 24/7 production Forecast sales revenues in the smart entertainment segment in Germany from 2014 to 2020 500 442.02 400 375.33 288.72 os 300 eur 196.82 200 124.65 100 81.52 s in millions of 58.73 enue v e R 0 2014 2015s 2016p 2017p 2018p 2019p 2020p Source: Statista (Digital Market Outlook) *All forecast values are marked © Statista 2015 with a p. 18�19

Rapid integration of new technologies and materials Perfect documentation of all process steps Industrie 4.0-ready from the design phase Hello Industrie 4.0�we connect you

Aerospace Perfection at new heights Without question, aircraft are the backbone of our global, mobile society. The requirement pro昀椀le for a modern aircraft is the equivalent of “squaring the circle”: designed for a decades-long product lifecycle, it must be capable of adapting chameleon-like to the fast-paced changes of technological developments, ecological requirements, customer expectations and safety standards. Implementing this variability in production on a competitive basis creates extremely demanding requirements in terms of the 昀氀exibility, e昀昀iciency and transparency of all processes in the value chain. This is a challenge that can only be met economically in the long term by the comprehensive intelligent networking of all components over the entire lifecycle of an aircraft. Today, a modern transport aircraft down to the levels of subassembly, parts are relevant to production. Our joint comprises about 昀椀ve million individual or raw material suppliers will lead to work together with manufacturers starts components that are produced by remarkable improvements in knowledge right from the design and development thousands of supply companies and input about potential weak points in an phase so as to optimally design compo- in the production sequence at precisely aircraft. nents and assemblies for automation the right time. Thus, the aviation indus- over the entire production process. try generates products with a simply mind-boggling range of variants. At pres- From virtual simulation through to As a result, we make a decisive contri- ent, there are more than 1,500 airlines automated production bution to creating future-oriented that order speci昀椀cally adapted versions. products in the aviation industry. At the Adding the suppliers, sub-suppliers and Even though it may sound like science same time, we provide for a humane maintenance providers to this results in 昀椀ction – with digitized production working environment and support an extremely multi-faceted supply chain. processes, we will not only be able to companies in coping with the lack of This closely intermeshed sequence of produce with greater 昀氀exibility and skilled workers. working steps means the quality of e昀昀iciency, but also detect problems long every individual part and every process before they have e昀昀ects on the practical can determine the reliability and safety functional capability of an aircraft. of the produced aircraft. Within this complex sequence, knowledge of details, As a result, the path for the aviation no matter how small, is an important industry towards the uncompromising commodity. Today, it is a standard digitization of all processes is pre-or- feature of the aircraft industry for all dained. The development and design of components that are essential for aircraft has long since been veri昀椀ed �Our automation solutions with a wide operation, such as the jet engines and supported by virtual simulations in variety of specialized end e昀昀ectors and control systems, to be monitored almost every area. This applies to physi- can be seamlessly integrated into the by sensors. The increasing, digitized cal/technical properties just as much networked production lines of the networking of production processes as to the de昀椀nition of all processes that aviation industry. 2020�21�21

Flexible and scalable systems provide dependable responses to market volatility Data analysis tools and arti昀椀cial intelligence provide trans- parency and provide predictive calculations of supply chain events Intelligent and mobile robotics is revolutionizing intralogistics Hello Industrie 4.0�we connect you

E-Commerce / Retail Smart automation of unpredictable processes Electronic commerce is setting new standards and challenging brick-and- mortar retailers. Fast delivery, maximum variety of products and absolute price transparency combined with seamless logistics are convincing advantages for online consumers. Smooth logistics necessitates digiti- zation of the supply chain and the implementation of automation solutions in warehouses. Business models in e-commerce demand highly 昀氀exible supply chains with a holistic approach that permits the seamless integration of retail, 昀椀nance and logistics processes into one transparent entity. Against this backdrop, solutions in e-commerce have to meet many demands simultaneously. These range from the interests of exclusively online retailers through to classic retail outlets and the distribution service provider or brand-name manufacturer. Mobile end devices, internet research Digitization is creating on the goods-to-person principle. Human- with a purchase option and exchange via intelligent intralogistics machine collaborations such as the social media have now become part and AutoPiQ order picking technology from parcel of the buying process. As a result, In the future ever more powerful fore- Swisslog are capable of opening up areas it is almost certain that the commercial casting tools will be available to the to automation that were previously an signi昀椀cance of e-commerce will increase retail sector that will be capable of exclusively manual domain. Particularly further in coming years. Even conservative predicting consumer behavior more forward-looking: even today Swisslog can estimates for the year 2020 predict on- accurately and will allow targeted adver- already seamlessly depict the transitions line sales in excess of 4 trillion US dollars. tising. Smart purchasing may require between the requirements in brick-and- The boundaries between online shopping only two clicks by the consumer, but it mortar retailing and e-commerce in and brick-and-mortar retailers are is based on extremely complex and hybrid systems. They are capable of both becoming more blurred and entering heterogeneous logistics networks – order picking for pallets and single-item into a long-term symbiosis. Whereas we characterized by a large number of data shipments from a warehouse. are currently still busy mapping the interfaces and an interchange between intermeshing of internal and external automated and manual activities, for logistics processes in real time, the trend example in the storage and picking of is moving towards predictive analytics goods. The latest automation technol- of the available mass of data. This means ogies from Swisslog are already provi- that we are using digital information ding the e-commerce and retail sectors �Industrie 4.0 solutions from 阀阀 intelligently enough to allow the next with networked software and robot- optimize the throughput of goods, consumer action to be predicted based logistics concepts that precisely minimize downtime and ensure both accurately. serve the nerve centers of the logistics transparency and high-speed responses chain – for instance, technologies based throughout the entire supply chain. 22�23

Consumer goods Customization requires production expertise. In actual fact, there is no such thing as “the” consumer goods market. Rather, there are dozens of them. No other market segment is as fragmented as the consumer goods segment. And scarcely any other market is facing such diverse challenges in coping with the future. However, they all have one thing in common: modern production concepts and logistics should support them in making their o昀昀erings even more 昀氀exible and suitable for customers, through to complete customization of mass-market products. Any company that intends to survive in this challenging sector in the long term really has no other choice: only consistently digitized processes and highly 昀氀exible, automated production and logistic systems are capable of e昀昀iciently bringing these customer-driven business models to a position of economic success. Solutions from 阀阀 take account of the entire value chain from manufacture through to packaging, logistics, sales and distribution. A look at the large shopping malls and Using digitization to mass-produce supermarkets leaves no room for doubt: unique products there is a massive variety of products in the consumer goods industry. In view of the enormous dynamics in the Foodstu昀昀s, clothing, personal hygiene consumer goods market, every future products, cleaning products – in each strategy for automation solutions must segment, the o昀昀ering is characterized by be capable of responding to new con- a large number of categories, sub- ditions e昀昀iciently and functionally. Here, categories, packaging sizes and types 阀阀 o昀昀ers digital concepts and techno- as well as di昀昀erent brands. In addition logies for agile control of integrated to the variety of items available, volatile value chains. Intelligent analysis pro- parameters in the business models are cedures use real-time data to precisely key factors in the success of the con- predict customer behavior and market sumer goods industry – for example, movements. It is not an exaggeration to global and regional trends, political say: any company that does not digitize in昀氀uences, new technological drivers, will be punished by the market. 阀阀 social taste and changes in values o昀昀ers customers a tailored solution for through to economic crises and natural each sector – in the area of Industrie 4.0 events. At the same time, it is apparent automation, this is achieved through that the number of product variants is the networking of the shop 昀氀oor with �Digital production permits business continuing to increase because of the data analytics tools, which enable us models that are individually adapted trend towards increasingly customized to better gauge the end users and their to customers and optimum control of products. responses. the entire process sequence. Hello Industrie 4.0�we connect you

Digitization and automation open up decisive potential for efficiency gains and cost reductions Transparency of all production and supply processes Establishment of planning and analysis instruments 24�25

Intelligent robots support treatments Optimization of material 昀氀ows and safe medication management Development of future technology for a digitized healthcare system Hello Industrie 4.0�we connect you

Healthcare Digital intelligence for perfect patient care Healthcare systems are coming under pressure from two sides: 昀椀rst, there is an obligation to keep costs down for running clinics, patient care and medication. Secondly, the quality demands for healthcare are rising in parallel to the aging of society. However, quite apart from the 昀椀nancial challenges and necessary e昀昀iciency increases in processes, what is ultimately important is the ongoing treatment success and patient welfare. With this goal in mind, we are creating modern automation systems for our customers which, for example, permit material 昀氀ow, 100 % traceability and safe medication management during and after hospital stays. The challenge of allowing everyone to With networked systems towards enjoy the best possible healthcare into proactive healthcare old age is reaching its limits in existing systems. This is because the costs of Beyond this, a comprehensive view of healthcare systems are rising at the same healthcare provision is crucial. This is why time as demand on them is growing due 阀阀 is working together with custom- to the ever aging population. In China, ers to produce integrated solutions Japan and Germany, the number of beginning with prevention and contin- people over the age of 67 will increase by uing to hospital stays, rehabilitation almost 50% in the coming decades. As and the sector of ambient assisted living. age increases, so does the intensity of Health data continuously gathered care – and thus the cost for healthcare from people by means of sensors as well systems. as the networking of medical databases will make it possible to establish a pro- �The healthcare system will bene昀椀t A whole series of technologies and active healthcare system. This means, from automation solutions in the concepts from the environment of for example, that routine examinations form of increased, logistical e昀昀iciency Industrie 4.0 can make a decisive and hospital stays for observation can and treatment methods improved contribution to breaking the “ever more be avoided. by robotics. expensive” trend and reducing the load placed on our healthcare systems. This includes the use of robot-supported automation solutions as assistants during treatment and aftercare as well as digital process optimization and intelligent monitoring technologies. 26�27

Holistic. Intelligent. Interconnected. KUKA identifies three key areas that open the door to tomorrow’s production.

�Consulting �Digital Domains �Intelligent Machines

Dr. Christian Schlögel Chief Technology O昀昀icer 阀阀 Aktiengesellschaft Hello Industrie 4.0�we connect you

» Those who act quickly and with foresight will have a handle on the future.« 30�31

The digitized world is incredibly fast. At times, products that were all the rage their 昀椀nger on the pulse will succeed, Production and logistics at the center just yesterday are considered boring or and those who miss the boat will lose of the storm old-fashioned at the blink of an eye. For out. Hyperconnectivity will enable new gadgets this may be the case within days, forms of production, spur many new The trend towards personal or individu- for clothing it may be weeks, for a car business models such as the shared alized products is already clearly notice- perhaps months or years. And of course economy, and the data will allow us to able in many manufacturing sectors. we expect products that highlight our make clear predictions. No matter It is highly likely that the variants of particular style and status, not just o昀昀- whether we are talking about consumer industrially manufactured products will the-shelf products. It is no surprise that behavior or the failure of a component proliferate explosively in the coming years. we can con昀椀gure our cereal online, and in a machine. And quantities will remain constant or we expect this high level of personaliza- increase slightly at the same time. But it tion and customization in virtually every Prosumers, consumers with more pro- would be wrong to think that optimiz- aspect of our personal and professional fessional demands on the product or who ing production and logistics processes life. may even directly impact the added and making them more 昀氀exible will value of a product as co-designers, will su昀昀ice. In the course of digitization, all For how long do people deem products challenge manufacturing and logistics communication within the value chain or services exciting? At what point do we in a completely new way. Many analysts will be restructured. Customer contact, become ambivalent to them, bored or even go so far as to predict that, in communication channels, distribution even get annoyed by them? There are the end, the best business model will channels – everything will change. In probably no generalized answers to win, and not the best technology. Even order to remain successful and address these questions. But they reveal the factor though we do not entirely agree with all of these aspects, companies must that is key to sustainable economic this opinion, it certainly points out that, take a holistic look at the possibilities, success: empathy for the market, adapt- in essence, it is about bringing products opportunities and challenges of ability and speed in implementation. and services to market maturity as Industrie 4.0. When implemented In the coming years, it is estimated that quickly and simply as possible. Speed in properly, Industrie 4.0 is a tremendous about 50 billion devices and 4 billion all of its forms is the decisive argument opportunity. For example, it is entirely people will be networked. Even today it of our time. realistic to assume that the combination is clear that this provides the foundation of a fast time-to-customer and the high for numerous new services and products demand for personalization renders it that will dramatically change the world necessary to produce closer to the con- as we know it today. And just like in sumer, or even to include the consumer all previous revolutions, the fourth in the product design as a co-producer. industrial revolution will be a blessing Intelligent automation with reduced and a curse at the same time. Those with manual e昀昀ort presents an opportunity to reshore outsourced or relocated production. Hello Industrie 4.0�we connect you

Holistic. Intelligent. Interconnected. Programmed for dynamism – Focus 4.0 First, we started using networked and Industrie 4.0 and IoT taken a more 昀氀exible production in our own fac- step further 阀阀 recognized the importance of the tories and our own robot production. fourth industrial revolution many years Next, we recognized early on that our The digital revolution is here. The com- ago and has strategically aligned itself concept of approaching Industrie 4.0 in bination of Industrie 4.0 and the Internet systematically to these new challenges a holisitic manner can only be imple- of Things probably o昀昀ers the greatest and topics. As a result, it is of no sur- mented with proprietary expertise in edge opportunity for the economy to realign prise that 阀阀 is amongst the world’s computing, our own IT hubs and our for a stronger future. In our opinion, the leading companies in this future-oriented own cloud platforms. For this reason, we existing consultancy sector is not capa- segment as one of the drivers of moved quickly and decisively to enhance ble of addressing this complex issue Industrie 4.0. We 昀椀rmly believe that our OT (operation technology) portfolio holistically. Contradictory statements or digitization will sustainably and irrevo- with IT expertise. We call this new isolated viewpoints from the individual cably transform the global economy. overall competence of OT and IT simply disciplines reinforce the uncertainty in Even if the technological cycles shorten, “Digital Domains”. Hidden behind this companies and inhibit the investment this topic will be the decisive factor for humble name is a core competence for propensity necessary for Industrie 4.0. industry over the next decades. And seamless and integrated digital net- But the technical groundwork has long that has consequences for the direction working of industrial production environ- been established. Today, 阀阀 is imple- of our own business as well. The world ments. A marriage between the real (OT) menting complex Industrie 4.0 scenarios is fast-paced, and this is sure to only and digital (IT) worlds. This involves in virtually every industry and to vastly increase in the future. To be successful, basic knowledge that gives us a decisive di昀昀erent degrees. In our opinion, the it is important to adapt swiftly. That edge even when seamlessly integrating actual risk is that companies will miss applies both to our customers and to our OT systems in existing or third-party their window of opportunity for trans- 阀阀 itself. This is why we have been IT infrastructures. We are now making formation and that they will eventually making changes over the past years and this accumulated in-house expertise be outdone by more agile competitors. will continue to do so in the future. available to our customers within the 阀阀 manufacturing ecosystem. 阀阀 has therefore asked the question of how we can use our own knowledge and our advanced global ecosystem, which includes relationships with research institutions, specialists, industry experts and much more, to signi昀椀cantly facili- Forecast global sales revenues with networked devices tate access to Industrie 4.0 for our cus- by sector in 2020 tomers. To make it safer, more needs- 950 driven and above all easier. Our answer 1,000 is very simple – we o昀昀er our customers direct access to our network of exper- 800 tise. No matter whether you require validation for new digital business models, 600 532.2 seek an exchange of experience in your US dollars industry, are looking to consult with Big Data specialists or if you require 400 expertise for a speci昀椀c manufacturing or 208.9 logistics process – the 阀阀 ecosystem s in billions of 200 o昀昀ers competent answers to all your enue questions. v e R 0 Smart Smart Smart mobility electronics M2M* Source: University of Jyväskylä *M2M stands for “Machine to Machine” © St atista 2016 (excluding PCs, laptops and smartphones). 32�33

Demographic change Home assisted living Robofactoring n=1 Ergonomic work Desire for customization Customized production within industrial manufacturing Hello Industrie 4.0�we connect you

Intelligent machines Interoperable systems for tomorrow’s production Unimaginable only a few years ago, but this knowledge with processes and few years back. Wherever the journey already entirely normal today: devices of systems in an intelligent way. These are takes us – in the future too, intelligent all kinds – whether autonomous lawn- parameters that are required for suc- robots will form the sturdy backbone mowers, thermostats, lamps, cars or cess in the networked world of IoT and of industrial production. They will not simply kitchen appliances – nowadays, Industrie 4.0. At the same time, they only be tethered within cells as we knew almost everything is capable of contact- take on a range of di昀昀erent guises. We them in the past, but provided with new ing other gadgets or data sources via know them as 3D printers, CNC machines intelligence, apps that are simple to inte- the Internet. Now, it is time to make or indeed as robots – probably the grate and give them new capabilities industrial production more agile, more most generic and versatile machine that at a click, or cloud-based functions that intelligent and more e昀昀icient along the human beings have ever thought up. turn them into active players in the same lines. This is done by endowing 昀氀exible, autonomously operating smart machines with the ability to develop factory. In contrast to Isaac Asimov’s themselves in an evolutionary way in a The backbone of the fourth industrial visions, this is not science 昀椀ction, but diverse range of forms and con昀椀gurations. revolution – intelligent robots actual, progressive reality. Among other things, they possess the capability of communicating with other 阀阀 recognized the potential of net- systems via the cloud – with production, worked and open automation systems workpieces or other machines. back in the 1990s. For example, in 1998 we introduced the world’s 昀椀rst inter- Intelligent machines that support operable, web-capable industrial robot humans cleverly, powerfully and safely onto the market. Possibly, it was those during their everyday work are a reality. machines that provided the impulse for Not in the humanlike form as Isaac Asimov the evolution which we currently know forecast in the 1950s: this is where as Industrie 4.0, or the fourth industrial reality departs from 昀椀ction. Machines revolution. It is a fact that no robot that join, assemble, transport and so today has any future unless it is capable on do not have to look like people. For of being integrated into complex, net- all intents and purposes, they only have worked production systems on the basis to accomplish three things: they must of standardized mainstream technologies. carry out their task as e昀昀iciently as And robots are continuing to develop possible, be able to adapt to new frame- further. In a variety of forms and con昀椀- work conditions as quickly as possible gurations, they are conquering areas and, in the future, be capable of sharing which were still closed to them only a 34�35

Cobots in industry Your robot colleague shares the work. In 1978, the cult band Kraftwerk re- Human beings remain at the leased a legendary piece of music under center of production the visionary-sounding title “The Man- Machine”. Today, this vision has become The crucial point is to achieve open com- reality. With sensitive robot colleagues, munication and simple integration. “cobots” for short, KUKA is demonstra- This makes cobots virtuosos for modern, ting that human-robot collaboration can networked production and logistics which be implemented today. will link together automation solutions with services and databases within the Sensitive cobots have the sense of touch foreseeable future. However, a factory required for the cyber-physical world staffed by robots alone will remain an of tomorrow’s production, in which IoT illusion, even in the smart factory. People and Industrie 4.0 will replace familiar will remain the central focus. However, structures. With their integrated sensors, robots will make people’s jobs less they make it possible to automate deli- arduous, will support people and give cate assembly tasks in the first place – them entirely new capabilities. ranging from assembling automotive transmissions through to inserting rubber This means the workers and logistics plugs or handling flexible parts. If unex- experts will be able to carry out their pected contact is made, cobots for jobs even more efficiently, with greater example reduce their speed and thus concentration and, above all, more the kinetic energy to an extent that ergonomically. This aspect is becoming prevents injury. When people and increasingly important, especially in a robots can work safely together, many society that is aging to an ever increasing conventional safety precautions become extent – worldwide. An ever smaller superfluous. Additional costs that number of people in employment will would normally be required for safety have to generate the entire productive technology and protective fences can output for the social systems. It will be dispensed with. Workers and robots only be possible to meet this challenge can share the same workspace without by employing the available workforce any concerns. In this way, expensive feed in a much more productive way than in systems and production floor space can all previous generations. With cobots be saved. in different payload categories, KUKA already offers central, key technologies Without doubt, cobots will play a key for a wide variety of tasks involving role in Industrie 4.0 – not only directly cooperation between humans and as part of modern production, but as machines: collaborative robots, mobile data gatherers that can communicate assistance systems, autonomously all relevant information to IT systems in controlled vehicles and intelligent, real time if required. Information that digitized automation solutions which can be processed immediately and sent reduce the burden on humans in a back to production. Knowledge that can variety of ways. be used for optimizing production suc- cessively or autonomously. At present, no other component in the production process is capable of carrying out this supporting role as well as modern robotic systems. Hello Industrie 4.0�we connect you

36�37

KMP omniMove Maneuvering huge components simple and safely on site: the KMP omniMove at the Airbus plant in Hamburg KMR QUANTEC KMP 1500 Intelligent robotics Maximum 昀氀exibility, right where it is unlimited mobility, needed: the mobile autonomous navigation: industrial robot the omnidirectional KMR QUANTEC stands mobile transport plat- for precision transport form KMP 1500 makes of even the heaviest for smart production components. environments. Hello Industrie 4.0�we connect you

Mobile robotics The path is the goal. Future production and logistics will have Maximum autonomy for in the most cramped conditions. This to expand like a spring. This means flexi- mobile robots and platforms means the logistics area can be reduced bility is called for, not only for accelerated by up to 50 %, allowing more space to manufacturing but also for customized KUKA Navigation Solution knows the be used for production. In addition, products. Guaranteeing this flexibility destination and the best way to get there. KMP omniMove vehicles effortlessly cope will require significantly greater mobility – This navigation solution responds spon- with loads of up to 100 metric tons. irrespective of whether the mobility taneously to obstacles and modifications, It could not be more mobile. concepts involved are episodic, periodic and coordinates all known vehicles in or permanent. For this reason, KUKA is the system. Fully in line with Industrie 4.0, laying the groundwork for this techno- its software ensures planning and logy – with platforms that move auto- implementation of orders in a coordi- nomously and intelligently to transport nated way – even in conjunction with items or process workpieces. Or with higher-level control systems. It registers platforms that find their own way if data from safety laser scanners and radar required, align themselves with work- sensors, and uses the SLAM method pieces with millimeter precision or (simultaneous localization and mapping) respond adaptively to changing conditions to create a detailed map of the sur- in demanding logistics and production roundings. By means of this map, the Infallible sense of orientation: sequences through autonomous behavior. platform can respond to changes in mobile automation solutions the surroundings, which are a matter from 阀阀 昀椀nd the way to their destination with unerring Our mobile automation solutions of course in a flexible logistics system. certainty even within highly provide the basis for the highly flexible It’s good to know that the software, complex production environments. production world of Industrie 4.0, in which is not dependent on a hardware With or without heavy loads. which rigid, assembly line concepts are platform, can be used for different kine- consigned to history, and the future matic systems. It enables any motion belongs to productivity spaces that principles to be handled – and of course can be continuously optimized. Even also holonomic vehicles with Mecanum complete production units can be wheels, such as the KMP omniMove. repositioned somewhere else on an ad hoc basis. This new type of mobility These vehicles offer unrestricted maneu- sounds like science fiction. But at KUKA, verability in every direction, including it is scientific fact. This means we are rotating the robot about its own axis. providing the blueprint for mobile auto- As a freely scalable modular system, it mation solutions with which every can be precisely adapted to the specific industrial company can gear up for the requirements in terms of size, length flexible, digitally networked world of and width. With its omnidirectional production. wheels, the vehicle can be used even 阀阀 昀氀exMOVER CarryPick Automated guided Designed to be modular vehicle for the and multifunctional, smart factory: CarryPick from Swisslog the 阀阀 昀氀exMOVER consists of mobile racks is the 昀氀exible helper and automated guided for all requirements, vehicles for goods-to- from the distribution person picking. of materials through to integration in complex assembly systems. 38�39

Humans and machines together Unlocking scope for flexibility Robots are establishing themselves in more and more 昀椀elds. According to the International Federation of Robotics (IFR), the number of industrial robots used worldwide will increase to about 2.6 million units by 2019. One of the driving factors is human-robot collabo- ration (HRC) made possible through innovative technology. 阀阀 is laying the groundwork for this with the LBR iiwa, the 昀椀rst industrially applicable, HRC- capable robot. Its sensitive sensors 阀阀 Navigation Solution permit seamless integration – without Intelligent orientation, any safety fence – and a division of Industry requirements occupy a central positioning, response. 阀阀 Navigation Solution labor between human and machine. role in the strategic orientation and knows the destination The human being controls and monitors de昀椀nition of these solution packages. and the best way to get production, the robot supplements the As a result, these packages have been there – every time. human’s capabilities and carries out developed jointly with customers and an extremely wide range of tasks as an specialists, and are tailor-made to the “Intelligent Industrial Work Assistent speci昀椀c tasks. (iiwa)”. The option of interacting with people, machines or workpieces ready2�use packages are combinations irrespective of location means that of 阀阀 software and hardware there is a practically unlimited range components which can be put into use of applications for this new generation immediately. In this way, the appropriate of mobile robotics. With its numerous package can be assembled by 阀阀 possible applications, the LBR iiwa is and the integrator to precisely match symbolic of the reality of Industrie 4.0. the customer’s automation experience. Added value through individual “ready2�use” solutions However, sometimes even maximum 昀氀exibility alone is not enough. Fast-paced branches of industry such as electronics or plastics require solutions and appli- cations that are ready for immediate use and easy to integrate. To meet the need for fast availability, 阀阀 has cooperated with some system partners to develop ready2�use solutions that can be im ple- 阀阀 昀氀exFELLOW mented by customers “out-of-the-box”. From manual to auto- mated in 10 minutes: the 阀阀 昀氀exFELLOW assists the operator 昀氀exibly and adaptably with a wide variety of tools that can be changed in a minute. Hello Industrie 4.0�we connect you

Safe and troublefree: 阀阀 HRC technologies make for relaxed interaction between humans and machines KMR iiwa An intelligent lightweight: the KMR iiwa combines the strengths of the sensitive lightweight robot LBR iiwa with a mobile, autonomously navigating platform. 40�41

KUKA Digital Domains Smart transformation to the digital world UI & Apps User Interface Cloud e Edg Shop 昀氀oor Hello Industrie 4.0�we connect you

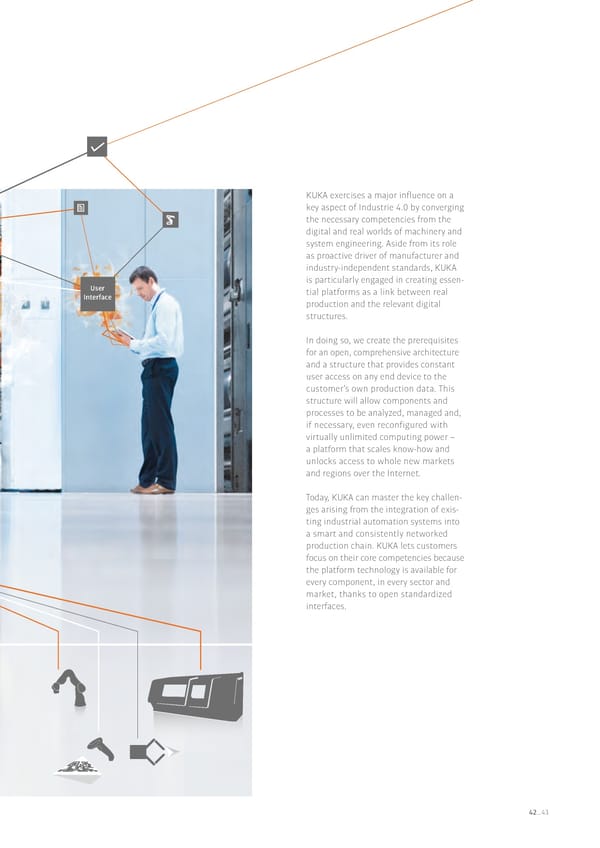

KUKA exercises a major influence on a key aspect of Industrie 4.0 by converging the necessary competencies from the digital and real worlds of machinery and system engineering. Aside from its role as proactive driver of manufacturer and industry-independent standards, KUKA is particularly engaged in creating essen- User tial platforms as a link between real Interface production and the relevant digital structures. In doing so, we create the prerequisites for an open, comprehensive architecture and a structure that provides constant user access on any end device to the customer’s own production data. This structure will allow components and processes to be analyzed, managed and, if necessary, even reconfigured with virtually unlimited computing power – a platform that scales know-how and unlocks access to whole new markets and regions over the Internet. Today, KUKA can master the key challen- ges arising from the integration of exis- ting industrial automation systems into a smart and consistently networked production chain. KUKA lets customers focus on their core competencies because the platform technology is available for every component, in every sector and market, thanks to open standardized interfaces. 4242�43�43

阀阀 Digital Domains Technical concept Shop floor / edge A trend can be identified across all cloud These services are directly integrated providers in which typical cloud func- into compact and, more importantly, As a first mover, KUKA has developed tions, like event processing, are shifted securely embedded computer systems open, interoperable and modular to the edge to increase closeness to the in the production environment for architecture layers and platforms for process and enable a more direct and cross-cell and cross-component tomorrow’s smart factory that ensure faster reaction in real time. Ultimately availability. efficient convergence of traditional this will lead to increasing centralization automation engineering with cloud of control and regulation tasks in the For end consumers and thus cell and technologies. cloud, instead of distributing them to system operators, it is important that various automation devices in decentral- data accessibility to their processes is Accordingly, every data transfer begins ized locations. enabled through minimally invasive with a production component or pro- edge integration. KUKA therefore cess, whose control and sensor system The edge is thus the crucial layer for strongly advocates the standardization communicates with peripheral equip- connecting real “things” on the shop floor and openness of interfaces to allow all ment via specific protocols and bus to the virtually infinite computing and production “things” to communicate systems. The edge provides the commu- storage capacity in the cloud. They can with the cloud via the same edge. nication interface between the cell also be incorporated into the new digital To this end, KUKA sits on established network (operation technology, OT) and world of Industrie 4.0 via the integration committees and promotes OPC UA as a overarching IT (information technology) of edge gateways in existing “brownfield” standardized communication protocol. network. Data are already consolidated, production plants. By contrast, when compressed, and encrypted in the local planning new “greenfield” plants, the Deep dive: the company is also pushing edge hardware before being transferred edge permits completely new control ahead with TSN (Time Sensitive Net- to the cloud. architectures in which an edge with working) expansion for deterministic high computing and real-time powers real-time communication via OPC UA acts as the central cell controller. and AMQP (Advanced Message Queue Protocol) for OPC UA cloud communica- As the edge layer interacts between tion. And, of course, KUKA draws on its things and the cloud, components are many years’ experience in remote main- relieved of requirements placed on cloud tenance of products at the edge and has communication, such as security, comput- recently extended its expertise through ing power, memory requirements, etc., participation in the Silicon Valley while at the same time being enhanced startup, Nebbiolo. by previously lacking cloud-compatible communication protocols. Hello Industrie 4.0�we connect you

Business cloud IT ERP / CRM Cloud MES / SCADA Production cloud y Edge e operabilit Edg er Int OT Shop 昀氀oor Brown昀椀eld Green昀椀eld 4444�45�45

The cloud layer – KUKA tailors its IoT platform develop- Business cloud – public, private, on the Internet ments to the requirements of MSEs in the production meets business intelligence. or on premises mechanical and systems engineering industry. After all, the platform is avail- The IoT platform manages thing-related The Internet of Things platform (IoT plat- able to enterprises from all sectors and data processing and evaluation. However, form) – included in the term “cloud” – can be used across all markets. Partners modern production systems also need is the next station for data sets after the can thus focus entirely on their core a uniform, structured approach to com- edge. But what is it actually all about? competencies and can access established prehensive value chain and maintenance micro services via KUKA’s IoT platform. processes. Since all things in production will be In addition, our partners and third-party communicating with the edge via stan- providers of services for programming And that is exactly what the business dardized protocols in the future, these and optimizing individual components cloud makes possible. It provides access, data are now sent to the cloud. In this or processes can also be integrated. for example, to all historically captured context, the cloud is a computer infra- A community based on partnership thus data for process and component analy- structure made available by providers evolves, driving the optimization of sis – such as the lifecycle or maintenance such as Microsoft or Amazon in the form components, processes and production information of individual robots. As a of “Infrastructure as a Service” (IaaS). operations via a shared technical result, processes can be launched and The IoT platform in turn describes a plat- platform. run digitally. form on one of these cloud infrastruc- tures – “Platform as a Service” (PaaS). Good to know: KUKA subsidiary connyun’s IoT platform is cloud-agnostic and can therefore run on any infrastructure. The customer can therefore freely choose whether this should be a private cloud, a public cloud (“anywhere” on the Internet) or on the customer’s premises. So-called micro services run on this plat- form, like for instance authentication, role concepts, Big Data storage and processing, etc. It also enables features such as artificial intelligence, predictive maintenance and event analytics. The IoT platform allows system operators to process the data from their producing things and to adapt processes on the basis of insights derived from the results. Hello Industrie 4.0�we connect you

Simple Updates Programming Process Analysis New Revenue User Interface Streams Intuitive Operation Complex Individual Analyses Community Dashboards Thanks to the standardized IoT platform UI, HMI & app layer – KUKA already possesses wide-ranging link to the customer’s business cloud, the basis for intelligent applications expertise and specialized staff in the all databases – of KUKA and its partners and human-machine interfaces field of app development, as has already alike – can be incorporated into the anal- been required for many years for the yses and quality assurance processes Human-machine interfaces (HMIs) allow local operation of components such as via this interface. customers to access IoT platform data robots. This is reflected, for example, and analysis results and to take the in the style guide for programming user Like many other customers, KUKA also required operator control actions. The interfaces, which supports the intuitive operates its own business cloud. The interface between the cloud and HMI operation of all HMIs. The so-called system offers customers an integral ex- end devices is also implemented by RESTful APIs allow our partners in the perience with KUKA across all points of means of open and documented APIs – KUKA Manufacturing Ecosystem to contact. In the future, our robot, cell and known in this case as RESTful APIs. implement the apps they need, designed system-specific data will additionally Community partners and other custom- exactly in accordance with their own be available to our community partners ers can thus program their own appli- ideas. Companies can thus not only on the IoT platform for improving cations for any end devices and evaluate access their own production data, but production efficiency. data supplied via the edge in line with also have them analyzed and evaluated their requirements. via the established micro services from The KUKA Marketplace including the KUKA and other third-party providers. App Store will also be operated via the Applications may have a very compact system. In practical terms, this means design and be used for highly specialized In the future, companies from all sectors, that the growing number of apps and and possibly component-specific tasks. such as system integrators, process, generated know-how can be marketed However, it is equally possible for complex hardware and software manufacturers, worldwide through this store – by a applications with a wide-ranging scope OEMs and start-ups will enhance their simple mouse-click. The benefit for cus- of functions to be implemented. In products, and especially their services, tomers: KUKA takes on the responsibility practice, requirements vary enormously with relevant apps. This scenario is for developing and operating the infra- depending on the sector, individual made possible by the KUKA Marketplace structure and places the process expertise production solutions and corporate with its App Store: programmed best available on the market at the commu- structures. Virtually no bounds are set – practice solutions can be bought and nity’s disposal in the form of applications. everything is covered from recording downloaded here, thereby giving the operating hours to optimizing the energy creators the opportunity to market their consumption of process sequences. know-how on a global scale. KUKA provides customers with a structured platform and broad community that offers all the relevant tools for quickly and efficiently integrating Industrie 4.0 solutions into the value chain in a dynamically growing ecosystem. 4646�47�47

KUKA Connect The smart KUKA robot Full transparency of in-production data By incorporating the data, KUKA also These services substantially reduce the through the intelligent connection of offers practical services for the robots. management requirements for operating various layers. KUKA has not only intro- For example, if a number of robots are the robots. Thanks to KUKA Connect, duced this model, but also puts it into deployed in a system, KUKA Connect laboriously compiled, redundant or even practice. The company has created and automatically calculates optimized main- contradictory documentation is now a launched the product KUKA Connect tenance cycles for them. The responsible thing of the past. Customers can access fully in keeping with the slogan “Practice technicians are immediately notified of long-term analyses of their robot systems what you preach”. Today, it already allows any service work required and the entire and can draw conclusions as to their customers to access and evaluate the history of each individual robot is saved incorporation in the process. usage and consumption-related data and made accessible. of their robots – from any end device, For this purpose, KUKA provides the anywhere and at any time. The award-winning knowledge database necessary infrastructure for its products “KUKA Xpert” is also integrated into and customers. For enterprises such as KUKA Connect is based on the layer the user interface – without the need system suppliers or line operators, model already described. If the for any complicated installation work. KUKA Connect opens up wide-ranging Nebbiolo box (edge) is integrated into This makes the many years of expertise possibilities for integrating KUKA robots a production cell, it automatically acquired by our service specialists into their concepts and operating them identifies the connected robots. The accessible worldwide and at all times. in their systems even more easily. harvested data are evaluated in the Up-to-date documentation and speci- cloud via the existing micro services fications, work instructions and demo in accordance with the customer’s videos, help in locating the right spare requirements. This enables system parts and troubleshooting based on operators to directly view the status qualified solution proposals – after and condition of their robots. more than ten years in field operation, KUKA Xpert has become a valuable companion for its users. Hello Industrie 4.0�we connect you

• Operation: production optimization • Maintenance: robot condition and monitoring, maintenance planning and schedule, anomaly detection and predictive maintenance • Service: remote management, 昀椀eld services, spare parts management and knowledge-based services • Resources: energy optimization and management • Data: static robot data and dynamic operating data

KUKA SmartProduction For seamless transparency across all processes Production lines consist of numerous KUKA SmartProduction enables all enter- sensors, actuators, network components, prises to consistently digitize whole and lots more. Virtually all these inte- cells and production lines. It creates an grated “things” are potentially valuable interoperable network, in which micro information providers, since processes services and Big Data analyses can be depend on the interaction of various used to analyze and lastingly improve components and peripheral properties. manufacturing efficiency, quality, and If the aim is to use data not only to opti- flexibility. With our open platform we mize individual components, but also offer component manufacturers, system to increase process quality, they must integrators, and machine operators be intelligently processed and visualized an additional channel for value-added together. KUKA SmartProduction gives services and applications for the system operators access to the information manufacturing industry. of process-relevant machines for eva- luation – in compliance, of course, with At the end of the day, the question the highest security standards and clear remains: what does the future hold for data association. medium-sized engineering enterprises? With KUKA SmartProduction, KUKA KUKA SmartProduction ensures easy, paves the way for enterprises across all seamless, and manufacturer-independent sectors to position themselves in the cross-sector linkage of all production digital world. The challenge and chance machines in the cloud. Designed for max- for those enterprises is to seize the imum freedom, KUKA SmartProduction opportunities while not losing touch can be deployed across different hard- with own core competencies. ware and software landscapes. KUKA solution’s standardized interfaces and KUKA invites you, too, to become an im- future-proof architecture make it the portant part of KUKA SmartProduction. ideal IoT platform for enterprises in all markets and sectors. Hello Industrie 4.0�we connect you

5050�51�51

Hello Industrie 4.0�we go digital

Clear. Competent. Comprehensive. The KUKA Consulting approach for Industrie 4.0 Let’s be clear on one point before we So, to summarize – Industrie 4.0 is com- The 阀阀 Consulting approach is based even begin to talk about Industrie 4.0 plex and integrative in equal parts. Yet, on a modular, 昀椀eld-tested procedure solutions: Industrie 4.0 is not a product if everyone is already doing Industrie 4.0, that always focuses on the customer’s or service as is often mistakenly assumed. how can we pull the strings together individual added value. We develop Neither is it a speci昀椀c technique, model, without dampening initiatives? On the solutions according to customer require- or method that can be simply bought contrary, how do we boost their syner- ments in three phases. An important and used. Industrie 4.0 de昀椀nitely con- gies? We enjoy a distinct status in the aspect is that various Industrie 4.0 cerns the product portfolio of estab- market through our 阀阀 Consulting solutions from 阀阀 and our partners lished machinery and system builders, approach, based on our long-standing are 昀椀rst trialed as prototypes to validate their market di昀昀erentiation and posi- industrial know-how and specialists their relevance and e昀昀ective added tioning. All in all, it concerns the entire to speci昀椀cally foster and demand the value at short notice within a customer enterprise. Close examination already relevant Industrie 4.0 skills. In doing so, context. Not Industrie 4.0 for the sake shows that virtually all corporate areas we abide by our hands-on mentality, of digitization, but Industrie 4.0 as an are a昀昀ected one way or another by the because successful Industrie 4.0 opportunity for the integral development subject and are already engaged in consultants earn their laurels on the of individual components, processes, developing measures for future viability. shop 昀氀oor and not in steering systems, or indeed entire corporate areas. committees. This diversity o昀昀ers huge potential to The intrinsic 昀氀exibility of the 阀阀 create a cross-departmental dynamic We have been pairing this know-how approach means that phases can be through interdisciplinary initiatives that with Industrie 4.0 approaches and asso- adjusted to speci昀椀c and changing needs unite the enterprise on the transforma- ciated technologies now for several years. and the pros and cons of particular ini- tion path. Compartmentalized projects This ongoing development of our core tiatives weighed before taking decisions. and mentality have no place in a world competencies makes us the ideal project The scope of a project and the involve- of digital opportunity. partner for digitizing production and ment of further partners is are thus entire business processes in enterprises de昀椀ned by the customer in the course of all sizes and in all sectors. The of the cooperation. 阀阀 supports the Industrie 4.0 accelerator team comple- customer throughout as a sparring ments this existing expertise through partner with sound experience and targeted partnerships with established process know-how. Along with our team specialists. Experts from precisely those of experts from the respective disciplines, areas vital to promote cross-company we can bring structure to the complexity Industrie 4.0 measures, to initiate their of our customers’ speci昀椀c challenges, targeted implementation and, if required, plan de昀椀ned steps, and put them into to provide support. practice as required. From left to right Industrie 4.0 Accelerator Team Rohitashwa Pant Dirk Engelbrecht Robert Kamischke » Industrie 4.0 consulting Holger Jaksch Dr. Kerstin Hö昀氀e starts on the shop 昀氀oor, Stefan Ampenberger not in steering committees.« Dr. Martin Lehl Jonas Podszuweit Christoph Groll Industrie 4.0 Accelerator Team 52�53

The 阀阀 3-phase model Your path to measurable results 阀阀 has a 昀椀rm grasp of the challenges At the end of the around three-week fully satis昀椀es their needs and expectations posed by engineering, process, cell and phase the customer receives a custo- in short iteration cycles. The scalability system automation, and the incorporation mized Industrie 4.0 maturity evaluation, and user friendliness of the solution in of logistics solutions. We also comple- a draft of areas for action and recommen- the enterprise is thus ensured. ment this know-how with experts from dations and, frequently, also a 昀椀rst areas vital to Industrie 4.0, such as IT Proof of Concept (PoC) in the customer’s security, Big Data Analytics, and business own production environment. At this Phase 3: model innovations. Enterprises can point, the expert consulting models to Pilot access this expertise via 阀阀 Consulting, be speci昀椀cally applied in the follow-up easing their entry into a world of constant phases are also de昀椀ned. After the Explore and Design & Prototype transformation and already producing Phases, implementation of speci昀椀c me- practical results in just a few weeks’ time. dium- to long-term projects is launched. We devise customized solutions in three Phase 2: Based on collective insights, technologies separate phases for maximum optimi- Design & Prototype and solution modules are now speci昀椀cally zation potential to achieve the set targets. implemented and entire system areas Customers obtain optimal, comprehen- The areas for action from the preceding further optimized in this way. Applying sive guidance from 阀阀 Consulting analysis are now dealt with and practi- the 阀阀 Consulting approach we ad- whether their goal is to increase plant cally implemented at the beginning of the dress the customer’s objectives through e昀昀iciency, reduce total cost of ownership Design & Prototype Phase. The customer Industrie 4.0-focused automation solu- (TCO), or automate a speci昀椀c process can choose which projects and starting tions, individual potentials through for future viability. points are to be launched initially or even digital services or innovative business in parallel. We draw on our experience models. The Pilot Phase acts as a spring- and incorporate various specialist areas board for various projects that com- Phase 1: which must be taken into account when prehensively secure the customer’s Explore implementing Industrie 4.0 measures enterprise for the digital future. Increased into the project procedure. These include e昀昀iciency, accessibility and analysis of During the Explore Phase we engage optimization, digitization and simulation process data, reduced cycle times, or the with the customer’s relevant stakeholders of production processes, IT architecture, creation of integrated system concepts to get a full picture of the customer’s and the relevant security setups. The are all practical examples of added value. expectations, requirements, and goals. immense potential of Industrie 4.0 for The customer obtains them in the initial The procedure, the necessary project extending and adjusting the customer’s phases of 阀阀 Consulting – respec- scopes and resources are speci昀椀ed in own business models is also explored tively customized to their objectives. the course of workshops and interviews. and addressed with the customer. The All in all, the 阀阀 Consulting approach At the same time, we de昀椀ne with the Proof of Concept can also be developed o昀昀ers a coordinated start to your customer key areas for action in the into a prototype based on the customer’s journey into the digital future. 昀椀elds of process design, technology requirements and then used as a test and deployment, production and cell layouts, evaluation environment for downstream organization, and IT structure. The rele- installations. As the result of the vant digitization aspects are highlighted, Design & Prototype Phase the customer which can be capitalized on through obtains a speci昀椀c test setup (process, Industrie 4.0. We de昀椀ne the projects cells, components), as the decision- with maximum enhancement potential making basis for implementation of and so-called quick wins, while always further projects along with the process applying established standards, documentation and analysis. The key lean management speci昀椀cations, aspect of this phase is to draft with the and manufacturing principles. customer an Industrie 4.0 solution that Hello Industrie 4.0�we connect you

Phase 1 Phase 2 Phase 3 Implement Proof of Concept Pilot I 4.0 Design & Scoping & Readiness Prototype Projects Review Gains Explore 阀阀 Consulting Potential & Gap Vision » 阀阀 Consulting has developed a stringent model for customized solutions.« Industrie 4.0 Accelerator Team 5454�55�55

阀阀 Consulting 阀阀 Consulting ering Industrie 4.0 Readiness IT Security & olution o昀昀 Architecture S Prototyping Business Smart Process & Model Logistics Innovation Handling ering Gluing Robotics em o昀昀 Machining st Screwing y S Future IT system proved landscape business model Virtual commis- sioning Material flow opti- mization Maturity model Hello Industrie 4.0�we connect you

阀阀 Consulting Keeping an eye on the big picture We have to broaden our view, break down In doing so, four structural areas are compartmentalization, and foster inter- particularly in昀氀uential and relevant operability if we want to make the most to the evaluation of the measures of Industrie 4.0. In technical terms this required for the digitization process. means cross-domain data management, data harvesting via proprietary interfaces, 1. Enterprise resources end-to-end management of cyber-physical (including the digital skills of employees security and creating integrated adminis- and production automation) tration, communication and logistics structures. To achieve increased produc- 2. Organizational structure tivity, we have to abandon established (including goals and strategic alignment structures and rethink every aspect of and organic internal organization) our business models. 3. Information systems 阀阀 o昀昀ers customers access to the (including horizontal and vertical necessary competencies to steer enter- integration as well as data delivery, prises quickly, simply and dynamically processing, storage, and transfer) towards Industrie 4.0 while taking their speci昀椀c needs into account. 4. Corporate culture (including focus on customer bene昀椀t, collaboration, and ongoing quali昀椀cation) Industrie 4.0 maturity Based on this analysis phase by our con- The technological maturity of production sulting partner UNITY, we 昀椀nd out how environments and their components is con昀椀dent employees are in handling IT crucial for the customer’s procedure systems (resources), whether and if so, and development towards Industrie 4.0. how cross-site information exchange As every enterprise has its own current works (organization structure) and whe- status of smart products and de昀椀nes its ther all employees are involved in pro- own Industrie 4.0 goals and, for example, duction optimization (corporate culture). general IT structures, customers need an Once the enterprise’s Industrie 4.0 individual approach of their own. This maturity rating has been established, status can be analyzed for each customer a digitization procedure can be de昀椀ned and then incorporated into the overall for the customer and e昀昀iciently imple- process. mented. An important aspect of this pro- cedure is that the right areas for exami- nation within the enterprise are selected from the outset. This makes it possible to take reliable stock of the current status and to derive appropriate goals. 56�57