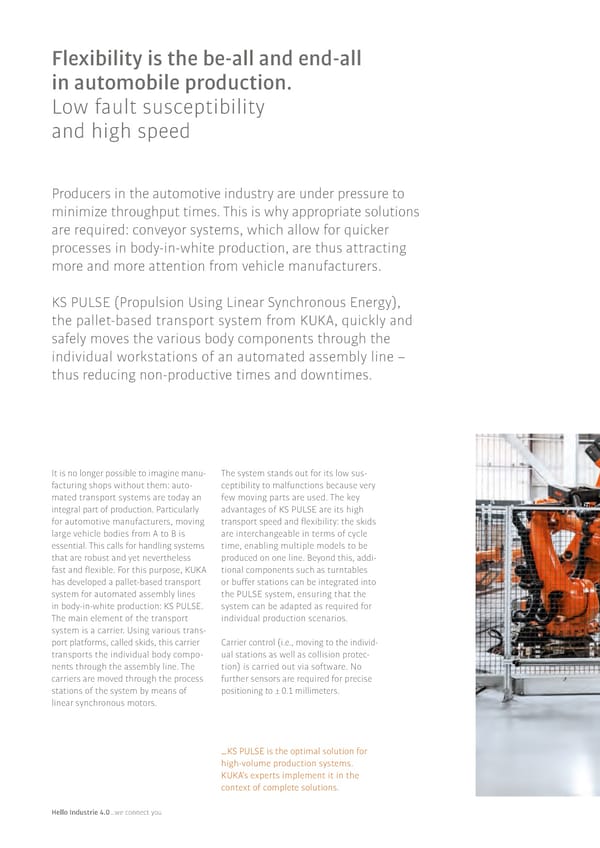

Flexibility is the be-all and end-all in automobile production. Low fault susceptibility and high speed Producers in the automotive industry are under pressure to minimize throughput times. This is why appropriate solutions are required: conveyor systems, which allow for quicker processes in body-in-white production, are thus attracting more and more attention from vehicle manufacturers. KS PULSE (Propulsion Using Linear Synchronous Energy), the pallet-based transport system from 阀阀, quickly and safely moves the various body components through the individual workstations of an automated assembly line – thus reducing non-productive times and downtimes. It is no longer possible to imagine manu- The system stands out for its low sus- facturing shops without them: auto- ceptibility to malfunctions because very mated transport systems are today an few moving parts are used. The key integral part of production. Particularly advantages of KS PULSE are its high for automotive manufacturers, moving transport speed and flexibility: the skids large vehicle bodies from A to B is are interchangeable in terms of cycle essential. This calls for handling systems time, enabling multiple models to be that are robust and yet nevertheless produced on one line. Beyond this, addi- fast and flexible. For this purpose, KUKA tional components such as turntables has developed a pallet-based transport or buffer stations can be integrated into system for automated assembly lines the PULSE system, ensuring that the in body-in-white production: KS PULSE. system can be adapted as required for The main element of the transport individual production scenarios. system is a carrier. Using various trans- port platforms, called skids, this carrier Carrier control (i.e., moving to the individ- transports the individual body compo- ual stations as well as collision protec- nents through the assembly line. The tion) is carried out via software. No carriers are moved through the process further sensors are required for precise stations of the system by means of positioning to ± 0.1 millimeters. linear synchronous motors. �KS PULSE is the optimal solution for high-volume production systems. KUKA’s experts implement it in the context of complete solutions. Hello Industrie 4.0�we connect you

Embracing Industrie Page 69 Page 71

Embracing Industrie Page 69 Page 71