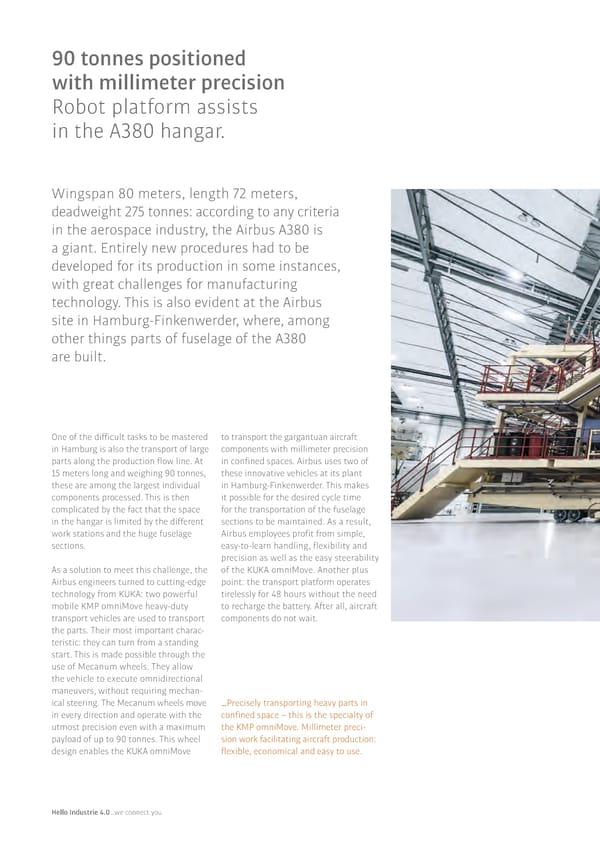

90 tonnes positioned with millimeter precision Robot platform assists in the A380 hangar. Wingspan 80 meters, length 72 meters, deadweight 275 tonnes: according to any criteria in the aerospace industry, the Airbus A380 is a giant. Entirely new procedures had to be developed for its production in some instances, with great challenges for manufacturing technology. This is also evident at the Airbus site in Hamburg-Finkenwerder, where, among other things parts of fuselage of the A380 are built. One of the difficult tasks to be mastered to transport the gargantuan aircraft in Hamburg is also the transport of large components with millimeter precision parts along the production flow line. At in confined spaces. Airbus uses two of 15 meters long and weighing 90 tonnes, these innovative vehicles at its plant these are among the largest individual in Hamburg-Finkenwerder. This makes components processed. This is then it possible for the desired cycle time complicated by the fact that the space for the transportation of the fuselage in the hangar is limited by the different sections to be maintained. As a result, work stations and the huge fuselage Airbus employees profit from simple, sections. easy-to-learn handling, flexibility and precision as well as the easy steerability As a solution to meet this challenge, the of the KUKA omniMove. Another plus Airbus engineers turned to cutting-edge point: the transport platform operates technology from KUKA: two powerful tirelessly for 48 hours without the need mobile KMP omniMove heavy-duty to recharge the battery. After all, aircraft transport vehicles are used to transport components do not wait. the parts. Their most important charac- teristic: they can turn from a standing start. This is made possible through the use of Mecanum wheels. They allow the vehicle to execute omnidirectional maneuvers, without requiring mechan- ical steering. The Mecanum wheels move �Precisely transporting heavy parts in in every direction and operate with the confined space – this is the specialty of utmost precision even with a maximum the KMP omniMove. Millimeter preci- payload of up to 90 tonnes. This wheel sion work facilitating aircraft production: design enables the KUKA omniMove flexible, economical and easy to use. Hello Industrie 4.0�we connect you

Embracing Industrie Page 73 Page 75

Embracing Industrie Page 73 Page 75