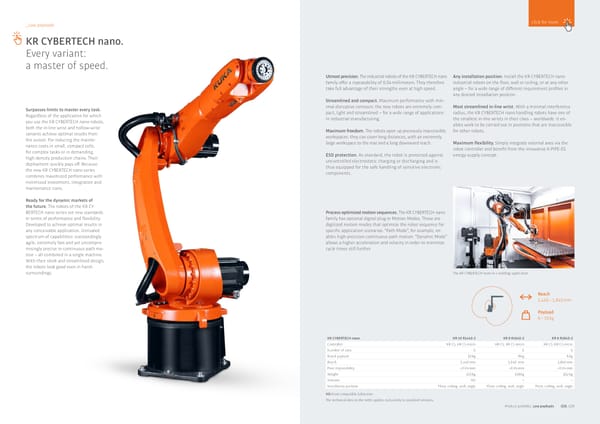

_Low payloads click for more KR CYBERTECH nano. Every variant: a master of speed. Utmost precision. The industrial robots of the KR CYBERTECH nano Any installation position. Install the KR CYBERTECH nano family o昀昀er a repeatability of 0.04 millimeters. They therefore industrial robots on the floor, wall or ceiling, or at any other take full advantage of their strengths even at high speed. angle – for a wide range of di昀昀erent requirement profiles in any desired installation position. Streamlined and compact. Maximum performance with min- Surpasses limits to master every task. imal disruptive contours: the new robots are extremely com- Most streamlined in-line wrist. With a minimal interference Regardless of the application for which pact, light and streamlined – for a wide range of applications radius, the KR CYBERTECH nano handling robots have one of you use the KR CYBERTECH nano robots, in industrial manufacturing. the smallest in-line wrists in their class – worldwide. It en- both the in-line wrist and hollow-wrist ables work to be carried out in positions that are inaccessible variants achieve optimal results from Maximum freedom. The robots open up previously inaccessible for other robots. the outset. For reducing the mainte- workspaces: they can cover long distances, with an extremely nance costs in small, compact cells, large workspace to the rear and a long downward reach. Maximum flexibility. Simply integrate external axes via the for complex tasks or in demanding, robot controller and benefit from the innovative K-PIPE-ES high-density production chains. Their ESD protection. As standard, the robot is protected against energy supply concept. deployment quickly pays o昀昀. Because uncontrolled electrostatic charging or discharging and is the new KR CYBERTECH nano series thus equipped for the safe handling of sensitive electronic combines maximized performance with components. minimized investment, integration and maintenance costs. Ready for the dynamic markets of the future. The robots of the KR CY- BERTECH nano series set new standards Process-optimized motion sequences. The KR CYBERTECH nano in terms of performance and flexibility. family has optional digital plug-in Motion Modes. These are Developed to achieve optimal results in digitized motion modes that optimize the robot sequence for any conceivable application. Unrivaled specific application scenarios. “Path Mode”, for example, en- spectrum of capabilities: outstandingly ables high-precision continuous-path motion. “Dynamic Mode” agile, extremely fast and yet uncompro- allows a higher acceleration and velocity in order to minimize misingly precise in continuous-path mo- cycle times still further. tion – all combined in a single machine. With their sleek and streamlined design, the robots look good even in harsh surroundings. The KR CYBERTECH nano in a welding application Reach 1,440 – 1,840 mm Payload 6 – 10 kg KR CYBERTECH nano KR 10 R1440-2 KR 8 R1640-2 KR 6 R1840-2 Controller KR C5, KR C5 micro KR C5, KR C5 micro KR C5, KR C5 micro Number of axes 6 6 6 Rated payload 10 kg 8 kg 6 kg Reach 1,440 mm 1,640 mm 1,840 mm Pose repeatability ±0.04 mm ±0.04 mm ±0.04 mm Weight 153 kg 158 kg 162 kg Variants HO – – Installation position Floor, ceiling, wall, angle Floor, ceiling, wall, angle Floor, ceiling, wall, angle HO Food compatible lubricants The technical data in the table applies exclusively to standard versions. Product portfolio_Low payloads 028_029

Product Portfolio Page 14 Page 16

Product Portfolio Page 14 Page 16