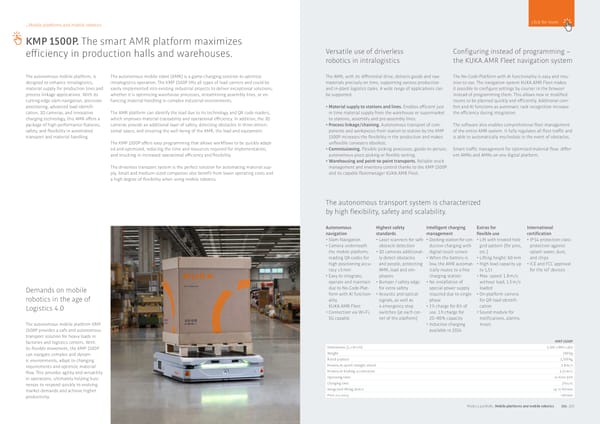

�Mobile platforms and mobile robotics click for more KMP 1500P. The smart AMR platform maximizes e昀昀iciency in production halls and warehouses. Versatile use of driverless Configuring instead of programming – robotics in intralogistics the 阀阀.AMR Fleet navigation system The autonomous mobile platform, is The autonomous mobile robot (AMR) is a game-changing solution to optimize The AMR, with its di昀昀erential drive, delivers goods and raw The No-Code-Platform with AI functionality is easy and intu- designed to enhance intralogistics, intralogistics operation. The KMP 1500P lifts all types of load carriers and could be materials precisely on time, supporting various production itive to use. The navigation system 阀阀.AMR Fleet makes material supply for production lines and easily implemented into existing industrial projects to deliver exceptional solutions, and in-plant logistics tasks. A wide range of applications can it possible to configure settings by courser in the browser process linkage applications. With its whether it is optimizing warehouse processes, streamlining assembly lines, or en- be supported. instead of programming them. This allows new or modified cutting-edge slam navigation, precision hancing material handling in complex industrial environments. routes to be planned quickly and e昀昀iciently. Additional com- positioning, advanced load identifi- • Material supply to stations and lines. Enables e昀昀icient just fort and AI functions as automatic rack recognition increase cation, 3D cameras, and innovative The AMR platform can identify the load due to its technology and QR code readers, in time material supply from the warehouse or supermarket the e昀昀iciency during integration. charging technology, this AMR o昀昀ers a which improves material traceability and operational e昀昀iciency. In addition, the 3D to stations, assembly and pre-assembly lines. package of high-performance features, cameras provide an additional layer of safety, detecting obstacles in three-dimen- • Process linkage/chaining. Autonomous transport of com- The software also enables comprehensive fleet management safety, and flexibility in automated sional space, and ensuring the well-being of the AMR, the load and equipment. ponents and workpieces from station to station by the KMP of the entire AMR system. It fully regulates all fleet tra昀昀ic and transport and material handling. 1500P increases the flexibility in the production and makes is able to automatically reschedule in the event of obstacles. The KMP 1500P o昀昀ers easy programming that allows workflows to be quickly adapt- unflexible conveyers obsolete. ed and optimized, reducing the time and resources required for implementation, • Commissioning. Flexible picking processes, goods-to-person, Smart tra昀昀ic management for optimized material flow: di昀昀er- and resulting in increased operational e昀昀iciency and flexibility. autonomous piece picking or flexible sorting. ent AMRs and AMRs on one digital platform. • Warehousing and point-to-point transports. Reliable stock The driverless transport system is the perfect solution for automating material sup- management and inventory control thanks to the KMP 1500P ply. Small and medium-sized companies also benefit from lower operating costs and and its capable fleetmanager 阀阀.AMR Fleet. a high degree of flexibility when using mobile robotics. The autonomous transport system is characterized by high flexibility, safety and scalability. Autonomous Highest safety Intelligent charging Extras for International navigation standards management flexible use certification • Slam-Navigation • Laser scanners for safe • Docking station for con- • Lift with treated hole • IP 54 protection class: • Camera underneath obstacle detection ductive charging with grid pattern (for pins, protection against the mobile platform, • 3D cameras additional- digital touch screen etc.) splash water, dust, reading QR-codes for ly detect obstacles • When the battery is • and chips Lifting height: 60 mm high positioning accu- and people, protecting low, the AMR automat- • High load capacity up • ICE and FCC approval racy ±5 mm AMR, load and em- ically routes to a free to 1,5 t for the IoT devices • Easy to integrate, ployees charging station. • Max. speed: 1.8 m/s operate and maintain • Bumper / safety edge • No installation of without load, 1.5 m/s Demands on mobile due to No-Code-Plat- for extra safety special power supply loaded form with AI function- • Acoustic and optical required due to single • On-platform camera robotics in the age of ality signals, as well as phase for QR load identifi- Logistics 4.0 阀阀.AMR Fleet 4 emergency stop • 2 h charge for 8 h of cation • Connection via Wi-Fi, switches (at each cor- use. 1 h charge for • Sound module for 5G capable ner of the platform) 20–80% capacity notifications, alarms, The autonomous mobile platform KMP • Inductive charging music 1500P provides a safe and autonomous available in 2024 transport solution for heavy loads in factories and logistics centers. With KMP 1500P its flexible movement, the KMP 1500P Dimensions (L × W × H) 1,300 × 900 × 263 can navigate complex and dynam- Weight 290 kg ic environments, adapt to changing Rated payload 1,500 kg requirements and optimize material Maximum speed straight ahead 1.8 m/s flow. This provides agility and versatility Maximum braking acceleration 1.25 m/s in operations, ultimately helping busi- Operating time at least 10 h nesses to respond quickly to evolving Charging time 2 hours market demands and achieve higher Integrated lifting device up to 60 mm productivity. Pose accuracy ±10 mm Product portfolio_Mobile platforms and mobile robotics 104_105

Product Portfolio Page 52 Page 54

Product Portfolio Page 52 Page 54