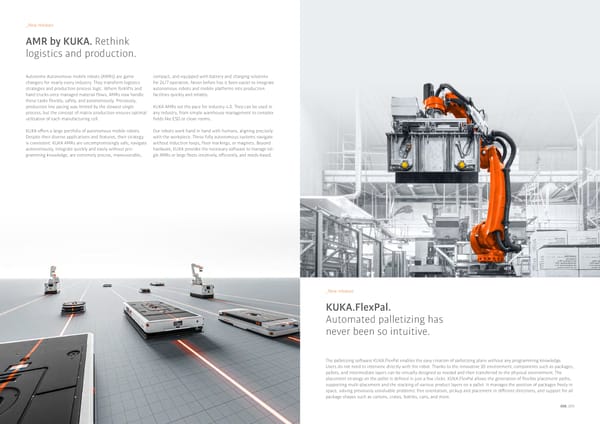

_New releases AMR by 阀阀. Rethink logistics and production. Autonome Autonomous mobile robots (AMRs) are game compact, and equipped with battery and charging solutions changers for nearly every industry. They transform logistics for 24/7 operation. Never before has it been easier to integrate strategies and production process logic. Where forklifts and autonomous robots and mobile platforms into production hand trucks once managed material flows, AMRs now handle facilities quickly and reliably. these tasks flexibly, safely, and autonomously. Previously, production line pacing was limited by the slowest single 阀阀 AMRs set the pace for Industry 4.0. They can be used in process, but the concept of matrix production ensures optimal any industry, from simple warehouse management to complex utilization of each manufacturing cell. fields like ESD or clean rooms. 阀阀 o昀昀ers a large portfolio of autonomous mobile robots. Our robots work hand in hand with humans, aligning precisely Despite their diverse applications and features, their strategy with the workpiece. These fully autonomous systems navigate is consistent: 阀阀 AMRs are uncompromisingly safe, navigate without induction loops, floor markings, or magnets. Beyond autonomously, integrate quickly and easily without pro- hardware, 阀阀 provides the necessary software to manage sin- gramming knowledge, are extremely precise, maneuverable, gle AMRs or large fleets intuitively, e昀昀iciently, and needs-based. _New releases 阀阀. FlexPal. Automated palletizing has never been so intuitive. The palletizing software 阀阀.FlexPal enables the easy creation of palletizing plans without any programming knowledge. Users do not need to intervene directly with the robot. Thanks to the innovative 3D environment, components such as packages, pallets, and intermediate layers can be virtually designed as needed and then transferred to the physical environment. The placement strategy on the pallet is defined in just a few clicks. 阀阀.FlexPal allows the generation of flexible placement paths, supporting multi-placement and the stacking of various product layers on a pallet. It manages the position of packages freely in space, solving previously unsolvable problems: free orientation, pickup and placement in di昀昀erent directions, and support for all package shapes such as cartons, crates, bottles, cans, and more. 008_009

Product Portfolio Page 4 Page 6

Product Portfolio Page 4 Page 6