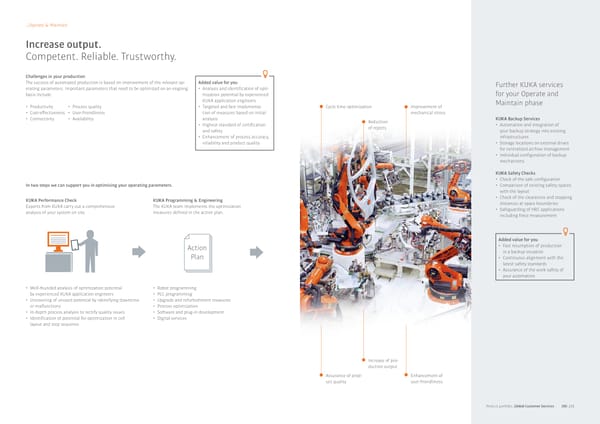

�Operate & Maintain Increase output. Competent. Reliable. Trustworthy. Challenges in your production The success of automated production is based on improvement of the relevant op- Added value for you Further 阀阀 services erating parameters. Important parameters that need to be optimized on an ongoing • Analysis and identification of opti- basis include: mization potential by experienced for your Operate and 阀阀 application engineers Maintain phase • Productivity • Process quality • Targeted and fast implementa- Cycle time optimization Improvement of • Cost-e昀昀ectiveness • User-friendliness tion of measures based on initial mechanical stress • Connectivity • Availability analysis Reduction 阀阀 Backup Services • Highest standard of certification of rejects • Automation and integration of and safety your backup strategy into existing • Enhancement of process accuracy, infrastructures reliability and product quality • Storage locations on external drives for centralized archive management • Individual configuration of backup mechanisms 阀阀 Safety Checks • Check of the safe configuration In two steps we can support you in optimizing your operating parameters. • Comparison of existing safety spaces with the layout 阀阀 Performance Check 阀阀 Programming & Engineering • Check of the clearances and stopping Experts from 阀阀 carry out a comprehensive The 阀阀 team implements the optimization distances at space boundaries analysis of your system on site. measures defined in the action plan. • Safeguarding of HRC applications including force measurement Added value for you • Fast resumption of production Action in a backup situation Plan • Continuous alignment with the latest safety standards • Assurance of the work safety of your automation • Well-founded analysis of optimization potential • Robot programming by experienced 阀阀 application engineers • PLC programming • Uncovering of unused potential by identifying downtime • Upgrade and refurbishment measures or malfunctions • Process optimization • In-depth process analysis to rectify quality issues • Software and plug-in development • Identification of potential for optimization in cell • Digital services layout and step sequence Increase of pro- duction output Assurance of prod- Enhancement of uct quality user-friendliness Product portfolio_Global Customer Services 190_191

Product Portfolio Page 95 Page 97

Product Portfolio Page 95 Page 97