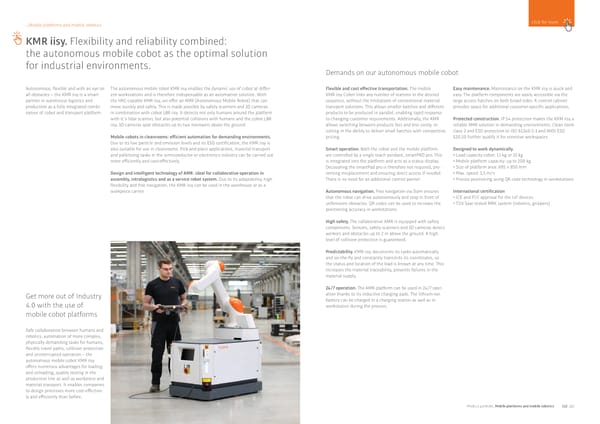

�Mobile platforms and mobile robotics click for more KMR iisy. Flexibility and reliability combined: the autonomous mobile cobot as the optimal solution for industrial environments. Demands on our autonomous mobile cobot Autonomous, flexible and with an eye on The autonomous mobile robot KMR iisy enables the dynamic use of cobot at di昀昀er- Flexible and cost e昀昀ective transportation. The mobile Easy maintenance. Maintenance on the KMR iisy is quick and all obstacles – the KMR iisy is a smart ent workstations and is therefore indispensable as an automation solution. With KMR iisy Cobot links any number of stations in the desired easy. The platform components are easily accessible via the partner in warehouse logistics and the HRC-capable KMR iisy, we o昀昀er an AMR (Autonomous Mobile Robot) that can sequence, without the limitations of conventional material large access hatches on both broad sides. A control cabinet production as a fully integrated combi- move quickly and safely. This is made possible by safety scanners and 3D cameras transport solutions. This allows smaller batches and di昀昀erent provides space for additional customer-specific applications. nation of cobot and transport platform. in combination with cobot LBR iisy. It detects not only humans around the platform products to be produced in parallel, enabling rapid response with it`s lidar scanner, but also potential collisions with humans and the cobot LBR to changing customer requirements. Additionally, the AMR Protected construction. IP 54 protection makes the KRM iisy a iisy. 3D cameras spot obstacles up to two meetwers above the ground. allows switching between products fast and less costly, re- reliable AMR solution in demanding environments. Clean room sulting in the ability to deliver small batches with competitive class 3 and ESD protection to ISO 61340-5-1 and ANSI ESD Mobile cobots in cleanrooms: e昀昀icient automation for demanding environments. pricing. S20.20 further qualify it for sensitive workspaces. Due to its low particle and emission levels and its ESD certification, the KMR iisy is also suitable for use in cleanrooms. Pick-and-place applications, material transport Smart operation. Both the cobot and the mobile platform Designed to work dynamically. and palletizing tasks in the semiconductor or electronics industry can be carried out are controlled by a single teach pendant, smartPAD pro. This • Load capacity cobot: 11 kg or 15 kg more e昀昀iciently and cost-e昀昀ectively. is integrated into the platform and acts as a status display. • Mobile platform capacity: up to 200 kg Decoupling the smartPad pro is therefore not required, pre- • Size of platform area: 695 × 850 mm Design and intelligent technology of AMR: ideal for collaborative operation in venting misplacement and ensuring direct access if needed. • Max. speed: 1,5 m/s assembly, intralogistics and as a service robot system. Due to its adaptability, high There is no need for an additional control pannel. • Precise positioning using QR code technology in workstations flexibility and free navigation, the KMR iisy can be used in the warehouse or as a workpiece carrier. Autonomous navigation. Free navigation via Slam ensures International certification that the robot can drive autonomously and stop in front of • ICE and FCC approval for the IoT devices unforeseen obstacles. QR codes can be used to increase the • TÜV Saar tested MRK system (robotics, grippers) positioning accuracy in workstations. High safety. The collaborative AMR is equipped with safety components. Sensors, safety scanners and 3D cameras detect workers and obstacles up to 2 m above the ground. A high level of collision protection is guaranteed. Predictability. KMR iisy documents its tasks automatically and on-the-fly and constantly transmits its coordinates, so the status and location of the load is known at any time. This increases the material traceability, prevents failures in the material supply. 24/7 operation. The AMR platform can be used in 24/7 oper- Get more out of Industry ation thanks to its inductive charging pads. The lithium-ion battery can be charged in a charging station as well as in 4.0 with the use of workstation during the process. mobile cobot platforms Safe collaboration between humans and robotics, automation of more complex, physically demanding tasks for humans, flexible travel paths, collision protection and uninterrupted operation – the autonomous mobile cobot KMR iisy o昀昀ers numerous advantages for loading and unloading, quality testing in the production line as well as workpiece and material transport. It enables companies to design processes more cost-e昀昀ective- ly and e昀昀iciently than before. Product portfolio_Mobile platforms and mobile robotics 112_113

Product Portfolio Page 56 Page 58

Product Portfolio Page 56 Page 58