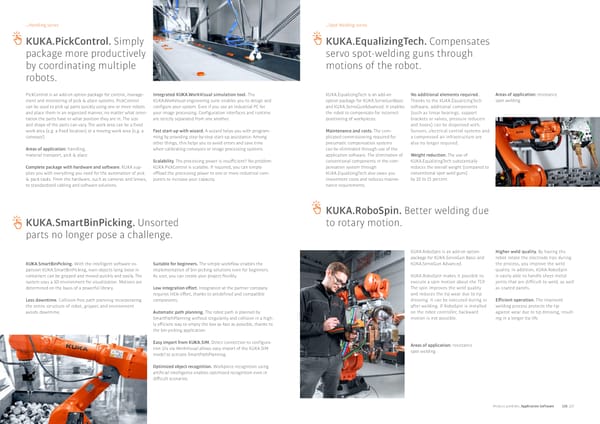

�Handling series �Spot Welding series 阀阀.PickControl. Simply 阀阀.EqualizingTech. Compensates package more productively servo spot-welding guns through by coordinating multiple motions of the robot. robots. PickControl is an add-on option package for control, manage- Integrated 阀阀.WorkVisual simulation tool. The 阀阀.EqualizingTech is an add-on No additional elements required. Areas of application: resistance ment and monitoring of pick & place systems. PickControl 阀阀.WorkVisual engineering suite enables you to design and option package for 阀阀.ServoGunBasic Thanks to the 阀阀.EqualizingTech spot welding can be used to pick up parts quickly using one or more robots configure your system. Even if you use an industrial PC for and 阀阀.ServoGunAdvanced. It enables software, additional components and place them in an organized manner, no matter what orien- your image processing. Configuration interfaces and runtime the robot to compensate for incorrect (such as linear bearings, support tation the parts have or what position they are in. The size are strictly separated from one another. positioning of workpieces. brackets or valves, pressure reducers and shape of the parts can vary. The work area can be a fixed and hoses) can be dispensed with. work area (e.g. a fixed location) or a moving work area (e.g. a Fast start-up with wizard. A wizard helps you with program- Maintenance and costs. The com- Sensors, electrical control systems and conveyor). ming by providing step-by-step start-up assistance: Among plicated commissioning required for a compressed air infrastructure are other things, this helps you to avoid errors and save time pneumatic compensation systems also no longer required. Areas of application: handling, when calibrating conveyors or image processing systems. can be eliminated through use of the material transport, pick & place application software. The elimination of Weight reduction. The use of Scalability. The processing power is insu昀昀icient? No problem: conventional components in the com- 阀阀.EqualizingTech substantially Complete package with hardware and software. 阀阀 sup- 阀阀.PickControl is scalable. If required, you can simply pensation system through reduces the overall weight (compared to plies you with everything you need for the automation of pick o昀昀load the processing power to one or more industrial com- 阀阀.EqualizingTech also saves you conventional spot weld guns) & pack tasks. From the hardware, such as cameras and lenses, puters to increase your capacity. investment costs and reduces mainte- by 10 to 15 percent. to standardized cabling and software solutions. nance requirements. 阀阀.RoboSpin. Better welding due 阀阀.SmartBinPicking. Unsorted to rotary motion. parts no longer pose a challenge. 阀阀.RoboSpin is an add-on option Higher weld quality. By having the package for 阀阀.ServoGun Basic and robot rotate the electrode tips during 阀阀.SmartBinPicking. With the intelligent software ex- Suitable for beginners. The simple workflow enables the 阀阀.ServoGun Advanced. the process, you improve the weld pansion 阀阀.SmartBinPicking, even objects lying loose in implementation of bin-picking solutions even for beginners. quality. In addition, 阀阀.RoboSpin containers can be gripped and moved quickly and easily. The As user, you can create your project flexibly. 阀阀.RoboSpin makes it possible to is easily able to handle sheet metal system uses a 3D environment for visualization. Motions are execute a spin motion about the TCP. joints that are difficult to weld, as well determined on the basis of a powerful library. Low integration e昀昀ort. Integration at the partner company The spin improves the weld quality as coated panels. requires little e昀昀ort, thanks to predefined and compatible and reduces the tip wear due to tip Less downtime. Collision-free path planning incorporating components. dressing. It can be executed during or E昀昀icient operation. The improved the entire structure of robot, gripper, and environment after welding. If RoboSpin is installed welding process protects the tip avoids downtime. Automatic path planning. The robot path is planned by on the robot controller, backward against wear due to tip dressing, result- SmartPathPlanning without singularity and collision in a high- motion is not possible. ing in a longer tip life. ly e昀昀icient way to empty the box as fast as possible, thanks to the bin-picking application. Easy import from 阀阀.SIM. Direct connection to configura- Areas of application: resistance tion UIs via WorkVisual allows easy import of the 阀阀.SIM spot welding model to activate SmartPathPlanning. Optimized object recognition. Workpiece recognition using artificial intelligence enables optimized recognition even in di昀昀icult scenarios. Product portfolio_Application Software 136_137

Product Portfolio Page 68 Page 70

Product Portfolio Page 68 Page 70